- Network Sites:

-

EEPower Day is a free 1-day virtual conference. Learn More

EEPower Day is a free 1-day virtual conference. Learn More

There are a lot of different capacitor types, all with their own applications, characteristics and construction. This page lists the different capacitor types which are described on the capacitor guide.

Air capacitors use air as a dielectric. Simplest air capacitors are made up of two conductive plates separated by an air gap. Air capacitors can be made a variable or fixed capacitance form. Fixed air capacitors are rarely used since there are many other types with superior characteristics.

Variable air capacitors are frequently used because of their simple construction. These are usually made of two sets of semicircular metal plates separated by air gaps. One set is fixed while the other is attached to a shaft that allows the user to rotate the assembly, therefore changing the capacitance as needed. The larger the overlap between the two sets of plates, the higher the capacitance. The maximum capacitance state is achieved when the overlap between the two sets of plates is highest, while the lowest capacitance state is achieved when there is no overlap.

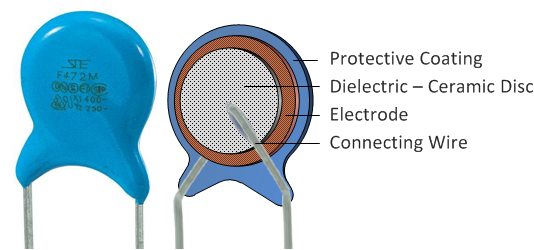

A ceramic capacitor uses a ceramic material as dielectric material. The most commonly used ceramic capacitors in modern electronics are muli-layer chip capacitor (MLCC) and ceramic disc capacitor. MLCC are made in SMD (surface-mounted) technology and is widely used due to its small size.

Typical values of capacitance ranging between 1nF and 1µF, although values are up to 100µF. Ceramic capacitors are unpolarized so they can be safely connected to an AC source, and have a great frequency response due to its low parasitic effects.

There are two classes of ceramic capacitors readily available today: class 1 and class 2. Class 1 is used when high stability and low loss is required. They are very accurate and its capacitance is very stable. Class 2 have high capacitance per volume and are mainly used for less sensitive applications.

This is the type of capacitor that uses an electrolyte to achieve a larger capacitance than other types of capacitor. An electrolyte is a liquid/gel that contains a high concentration of ions. Almost all electrolytic capacitor are polarized making the voltage at the positive terminal always greater than the negative terminal.

The benefit of its large capacitance comes with several drawbacks. Among these are large leak currents, value tolerances of around 20%, equivalent series resistance and limited lifetime.

Electrolytic capacitors can be wet-electrolyte or solid polymer. Electrolytic capacitor have a typical value of capacitance between 1µF and 47mF and an operating voltage of up to a few hundred volts.

Supercapacitors are electronic devices which can store extremely large amounts of electrical charge. Supercapacitors are special subtype of electrolytic capacitors and is known as double-layer capacitors or ultracapacitor. It is a polar device, requiring it to be correctly connected in the circuit.

Supercapacitors use two mechanisms to store electrical energy instead of using a conventional dielectric, : pseudocapacitance and double-layer capacitance.Double layer capacitance is electrostatic in origin, while pseudocapacitance is electrochemical, which means that supercapacitors combine the functions of normal capacitors with the functions of an ordinary battery. Capacitances achieved using this technology can reach up to 12000 F.

Whilst an ordinary electrostatic capacitor can have a high maximum operating voltage, the typical maximum charge voltage of a supercapacitor lies between 2.5 and 2.7 volts. The fast charge and discharge property of these devices are very interesting for some applications, where supercapacitors may completely replace batteries.

This type of capacitor is another subtype of the electrolytic capacitor. They are made of tantalum metal that acts as an anode, covered by a layer of oxide that acts as the dielectric, surrounded by conductive cathode. Tantalum allows for a very thin dielectric layer resulting in a higher capacitance value per volume, superior frequency characteristics compared to other types of capacitors and excellent stability over time.

Tantalum capacitors are generally polarized requiring them to be correctly connected in the circuit. Its downside is its unfavorable failure mode that leads to thermal runaway, small explosions and fires which can be prevented by using external failsafe devices like current limiter or thermal fuse.

Technology advances allow tantalum capacitors to be used in a wide variety of circuits, often found in the automotive industry, laptops, cell phones and others, most often in the form of surface mounted devices (SMD). These surface mount tantalum capacitors claim much less space on the printed circuit board (PCB) and allow for greater packing densities.